![]()

![]()

CASING CENTRALIZERS

MTS centralizers are non-weld with hinges and lips kept integral with the Collars. These are best designed to have their versatile applications. The construction of the Centralizers assures that hinges will not open while casing is being run regardless of hole direction or irregularities in formations. The Centralizers will provide effective centering down the hole.

The Spring Bows, the critical parts of the Centralizer, are made of high quality special steel strips. Bows are forged in four different unique designs to have varied heights. These are then hardened and tempered to ensure optimum mechanical properties to meet or exceed the STARTING & RESTORING FORCE criteria specified in A.P.I. Standard 10-D. Bows are then flattened several times on a special machine to get permanent setting.

End Collars made of steel that meet ASTM A 569 specification.

End Collars hinges that are folded to the inside. This acts to minimise the Collar stretch that tends to occur when Centralizers encounter tapers common to some pipe connections.

STABILIZERS - SLEEVE

The 25 Stabilizers consists of one piece body, on which a sleeve is simply made up by conj or sleeve breaker, on the rig floor. These stabilizers provide versality and easy sleeve replacem,ent to adapt to different formations and for hole sizes - 81/2", 121/4", 171/2" and 26".

The body of these stabilizers is made of AISI 4145H modified alloy steel, fully heat treated to 285-341 Brinell hardness and 52 Joules minimum impact strength. Connections are cold rolled, phosphatized coated and equipped with thread protectors. Connections are gauged to API standards.

MTS Sleeve Stabilizers is one of the best sleeve stabilizers for drilling operations and especially for directional drilling. For each body size, a wide range of sleeves can be filled.

STABILIZERS - INTEGRAL

MTS integral blade stabilizers has a single piece body made of 4145H modified alloy steel, fully heat treated to 285-341 Brinell hardness and 40 Joules minimum impact strength. these are available in either open design or tight design, near bit or string type - for hole sizes 61/8" to 26".

SUCKER RODS & COUPLINGS

MTS Sucker Rods & Pony Rods are made from Chrome, Molybdenum alloy steel. The rod ends are upset by special forging machines to ensure the most favorable grain structure. Full length rods are heat treated to achieve the specified mechanical properties after forging. The forged ends are machined and threaded in conformity to API specification 11-B. The threads are duly checked with API Gauges.

Rods are manufactured in 25 ft to 30 ft length and in 1/2", 5/8", 3/4", 7/8", 1" & 1.1/8" size. Pony Rods are also manufactured in all sizes. Sucker Rods & Pony Rods and specially their threaded ends are given non-metallic type phosphate coating for protection against corrosion and for antigalling treatment while tightening.

MTS Sucker Rods offers a full line of API grade Sucker Rods- grade K, grade C, grade MD, grade D and grade KD.

All Sucker Rods are threaded and packed as per API, 11-B, providing sets of spacers to avoid getting bent during transit and storage.

DRILL COLLARS

MTS supplies short length Drill Collar in all O.D. sizes strictly as per API specification, these are made from alloy steel AISI 4145H and heat treated to meet the specified properties.

Re-threading of Drill Collars & Drill Pipes are on Oil Country Machine. Threads are cut with a constant profile tool to ensure the highest accuracy possible. Cold rolling is systematically carried out on a special machine to improve mechanical properties of the connections. Before thread cutting, ends are tested for fatigue cracks.

ROTARY SUBS & KELLY SAVER SUBS

All Crossovers / Substitutes are made out of Ultrasonically tested AISI 4145H modified alloy steel. these are fully heat treated to a Brinell hardness range of 285-341 and have an Izod impact strength of 40 ft/lb minimum. The substitutes are made in all sizes as per requirement of customers.

All connections are machined and finished according to API standards, thread root are cold rolled. Connections are phorphatized.

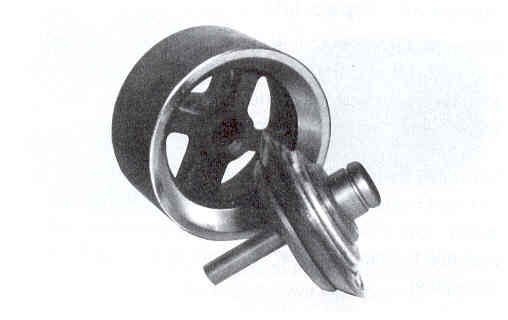

VALVE ASSEMBLY & VALVES SEATS

MTS valves assembly, valve body, valve seats, valve inserts, split locks, snap rings and guide etc. are given optimum mechanical properties so that the assembly does not fail under the stress of pressure, speed, temperature and corrosive fluids.

The valves inserts are manufacture from special synthetic rubber compound and is die moulded under controlled conditions of temperature, pressure and time. The split lock plates are also heat treated to provide enough strength. The Knock on plate is steel casted, hardened and tempered for good strength.

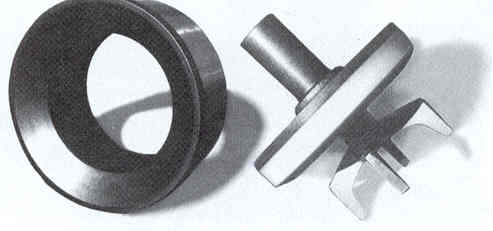

SLUSH PUMP LINERS

All LU Liners carry the authorised API Monogram certifying their compliance to standards.

MTS offers two grades of Liners. Each grade has been made to provide maximum service life, performance and efficiency for its respective application.

The tough high chrome bore is honed and polished to a mirror finish in the range of eight Micro inches with a hard wear surface of 63-65 HRC and produces outstanding resistance to extreme abrasion corrosion and friction.

These Liners are available for both Duplex & Triplex Pumps, and designed for medium to heavy duty operation.

These Liners are manufactured from Nickel Chrome alloy steel forgings. These are hardened to H.R.C 58-62 and ground finished to the close tolerances and micro inch finish.

ROTARY REAMERS

MTS offers two types of rotary Reamers, one featuring standard cutter assembly, and the other sealed bearing cutter assembly. These two Rotary Reamers types allow to meet all reaming conditions and formations.

For all sizes both these types are inter changeable on the same body, therefore reducing spare requirements and optimizing field maintenance and drilling performance. These would suit all standard reaming conditions and would provide maximum duration life of the cutting surface in hard and for abrasive formations.